From history to the present

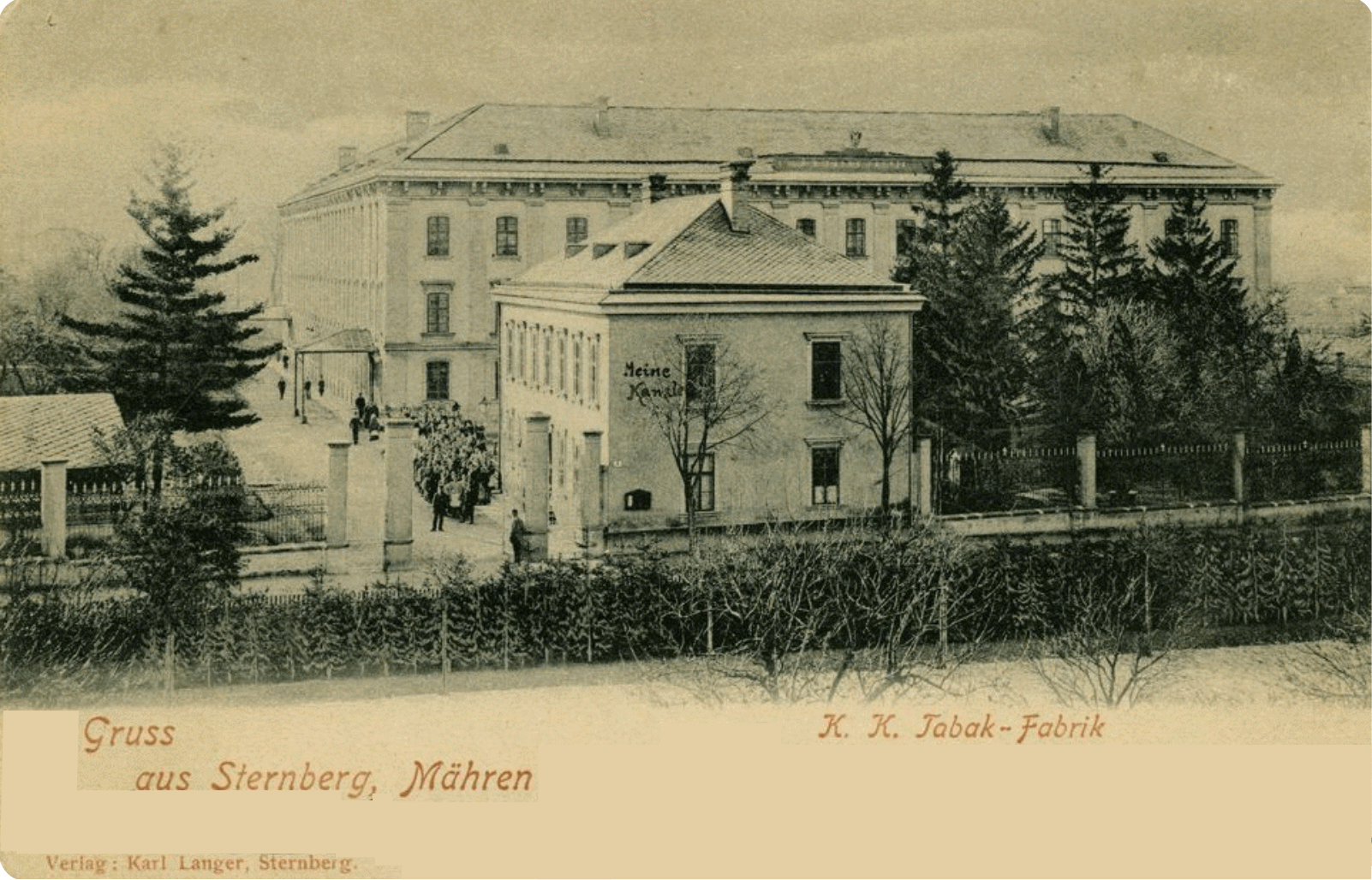

1875 -1939 Tobacco factory

The history of the production area dates back to the time of Austria-Hungary, namely the years 1874–75, when a new modern factory for tobacco production was built in Sternberg on Bahn-Straße (Nádražní Street).

The state tobacco factory produced about 10 million cigars and over a billion cigarettes a year, employed up to 1,600 people and operated as the most prosperous industry in Sternberg until World War II.

During World War II, tobacco production was suspended and the premises were used primarily for the needs of the war front.

1947-1992 Chronotechna

It was not until 1947, when the state decided to establish a watch industry, that the tobacco factory building could be extensively renovated and the necessary machinery and equipment for alarm clocks installed, creating one of the most important watch companies in Central Europe, the national company Chronotechna.

The PRIM brand was one of the most important brands in the Czechoslovak industry. At the time of its largest activity, Chronotechna Šternberk employed up to 2,100 workers. It had a total of 5 production plants in Brno, Nové Město nad Metují, Strání and Gelnice (SK). It offered a range of more than 140 timepiece products, from watches to wall clocks, which were exported to 80 countries around the world.

Production was not only focused on alarm clocks and clocks, but also produced timers, tachographs, metronomes, automatic parachute releases, tools, mechanical, later electrical cash registers and other products.

since 1992 EUTECH joint-stock company

In 1992, during the privatization of EUTECH, a joint-stock company was established, which is the successor company of Chronotechna.

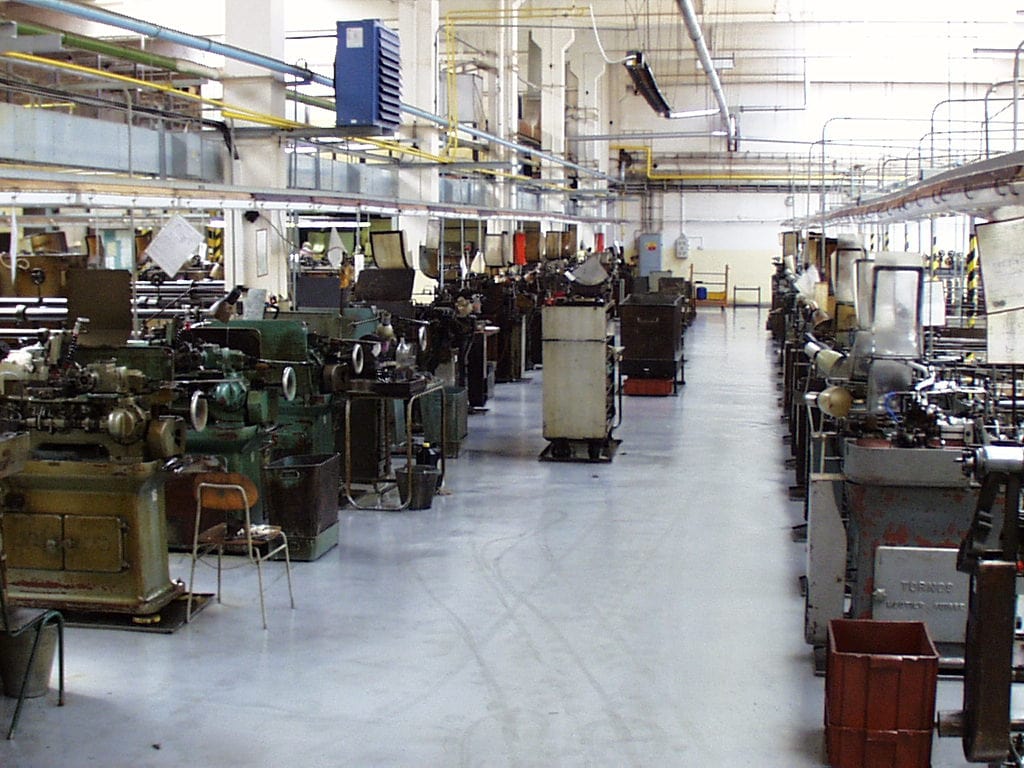

After the end of the production of alarm clocks in 2001, the joint-stock company EUTECH continues in the tradition of engineering production and specializes in the production of precision parts intended for serial production, production of tools and molds for plastic injection.

At present, EUTECH join-stock company is a purely Czech company. Every year, the company invests in new modern technologies. In the Metalworking Division, the machine park has been significantly renewed over the last 10 years. The original cam automatic machines were replaced by modern four- to eight-axis CNC long-turning lathes, which produce in continuous operation. A large part of the production is exported abroad.

The Tool Shop Division specializes in the production of molds for moldings intended primarily for the automotive industry. These are mainly molds producing lighting technology. This segment requires particularly high precision molds.

The watchmaking tradition is used in the production and assembly of special safety devices for the aerospace industry, thanks to which EUTECH has secured a significant market position.

The company has been a certified supplier since 1999.

Company vision

To become the first choice of customers for its credibility, reliability, quality of work performed, to be an attractive employer with satisfied employees and to be a socially responsible company.